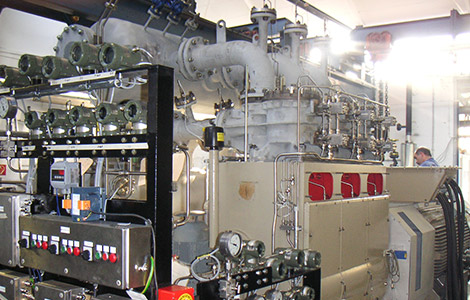

Steam injection in the combustion chamber of a gas turbine to reduce the NOX values in the exhaust gas flow.

On installing a gas extraction plant in the Mideast, the operator was confronted with environmental regulations regarding the reduction of NOX values when operating his gas turbines shortly before construction was completed. To this purpose high pressure steam was to be injected into the exhaust steam flow of the turbines.

However, there was not sufficient space for an additional steam generating plant on the site, the construction of which was already advanced. The solution: the installation of a Spilling steam compressor for the targeted provisioning of the required high pressure steam.